There are many ways to air roast coffee

Read on to understand the differences

Humans have been roasting coffee for hundreds of years.

In the early days, coffee was roasted in a pan over an open fire. These crude roasting methods gave way to more sophisticated appliances. To this day, most coffee is roasted in a cylindrical container rotating over a heat source. Think of it as a rotating frying pan.

Fast forward to 1974

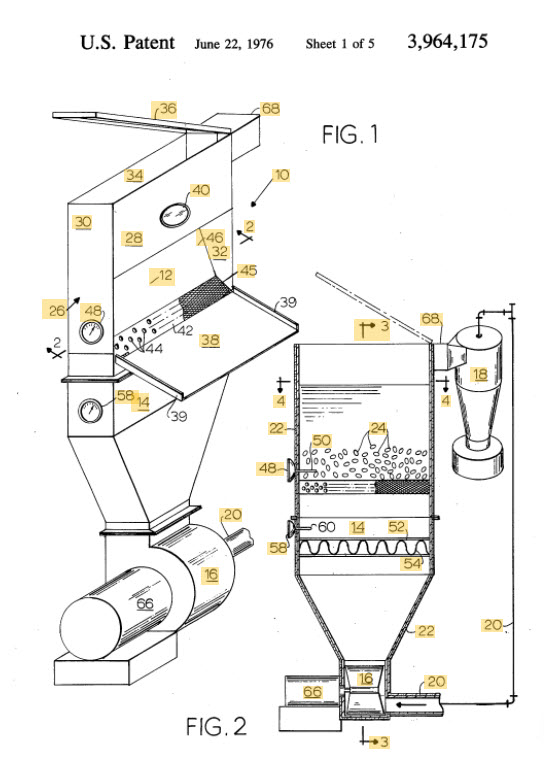

Mike Sivitz, a world coffee authority, invents and patents the technique of roasting coffee suspended by air in a fluidized air bed.

His invention embodies two characteristics that define Air Coffee Roasting.

- Mixing the coffee beans by levitation on a cushion of air.

- Using the heated levitating air to roast the coffee.

Read on to understand the many and varied ways this can be accomplished.

Michael Sivetz US Patent US3964175A Illustration

Rotating, Percolating & Spouting: How do they differ?

Rotating Fluidized Bed

Heated fluidizing air enters the chamber at the bottom front (left) of the roasting chamber. The roasting air lifts the coffee beans then escapes through the top of the roaster.

Chinook Air Coffee Roasters utilize this technique exclusively in all our coffee roasters.

Percolating FLUIDIZED BED

The coffee beans are contained in a chamber having a flat bottom with evenly spaced holes. The hot roasting air enters from the bottom mixing the coffee during roasting.

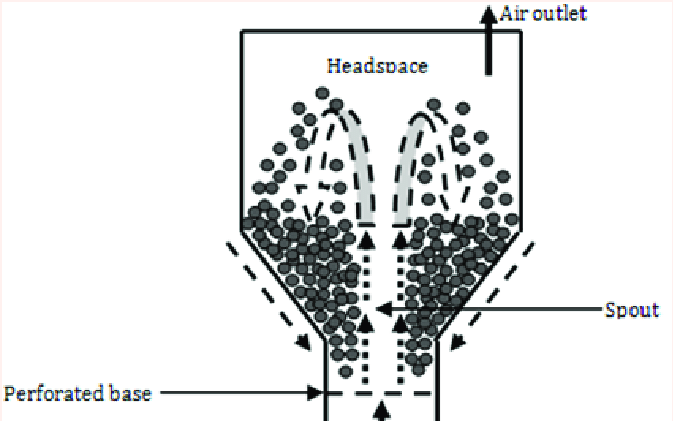

Spouting FLUIDIZED BED

The coffee beans are contained in a cylindrical chamber having a cone at the bottom. The bottom tip of the cone has a small round flat plate with evenly spaced holes. The hot roasting air enters through the round bottom plate. The mixing of the coffee produces a spouting motion during roasting.

The Percolating Fluidized Air Bed.

This fluidizing method lifts all coffee beans simultaneously. As a result, the roasting air is thoroughly mixed with all the coffee beans.

Precise control of the coffee roasting process requires the accurate and exclusive measurement of the coffee bean temperature. This is impossible as the roasting air is present throughout the roasting chamber.

Hence, the roasting process monitors the roasting air exhaust temperature. This exhaust temperature provides a relative indication of the roasting progress.

The example at the right is from the Sonofresco Products Video Another percolating fluidized air bed coffee roaster is manufactured by Typhoon roasters.

The Spouting Fluidized Air Bed

This fluidizing method lifts the coffee beans in a spouting motion directly off the bottom centre of the cylindrical roasting chamber. As a result, the roasting air levitates and roasts the coffee beans which return to the bottom in the surrounding layer of beans between the spout and the cylinder wall.

The roasting process is monitored by a temperature probe inserted through the cylinder wall which measures the temperature of the coffee beans returning to the bottom of the cylinder. This provides an indication of the roasting progress.

The example above & drawing at the right is of an early Sivetz 8 Lb spouting coffee roaster. Other air roasting manufactures using this method are Coffee Crafters, Air-Motion Roasters, etc.

The Rotating Fluidized Air Bed

The rotating fluidizing method lifts the coffee beans in a wall across the front of the roasting chamber. As a result, the roasting air levitates and roasts the coffee beans straight up which then fall back and return to the bottom by sliding down the sloped back wall of the roasting chamber.

The roasting process is monitored by a temperature probe inserted parallel to the back wall which measures the temperature of only the coffee beans returning to the bottom for levitation.

The proximity of this probe to only the coffee beans provides the most accurate bean temperature measurement of any fluidizing method.

The example at the right is from NEUHAUS NEOTEC RFB Roasting Chamber. All Chinook Roasting Systems, from 500 gm batch to 300+ Kgs/hour, use the Rotating Fluidized Air Bed method, see below.

Chinook Coffee Roasters… use the RFB method Exclusively

The Rotating Fluidized Bed (RFB) provides many advantages to the Roasting Operator.

No moving parts in the roasting chamber result in dramatically reduced maintenance costs. Accurately measuring bean temperature 10 times/second assures the Chinook will produce batch to batch consistency cold or hot.

- Even Roasting as the roasting air mixes the coffee beans

- Each coffee bean exposed to the same temperature Clean Result as all debris are removed by the vigorous air mixing

- Accurate coffee bean temperature monitoring

- Accurate roasting air temperature monitoring & control

- Elegant simplicity results in reduced maintenance cost