Chinook system 400kgs hour

The Chinook50Kg2C includes:

2.3 Tonnes green coffee supply X 4 Single Origins

Computerised weighing of batch & blends

Pneumatic transport of green coffee to roaster receiver

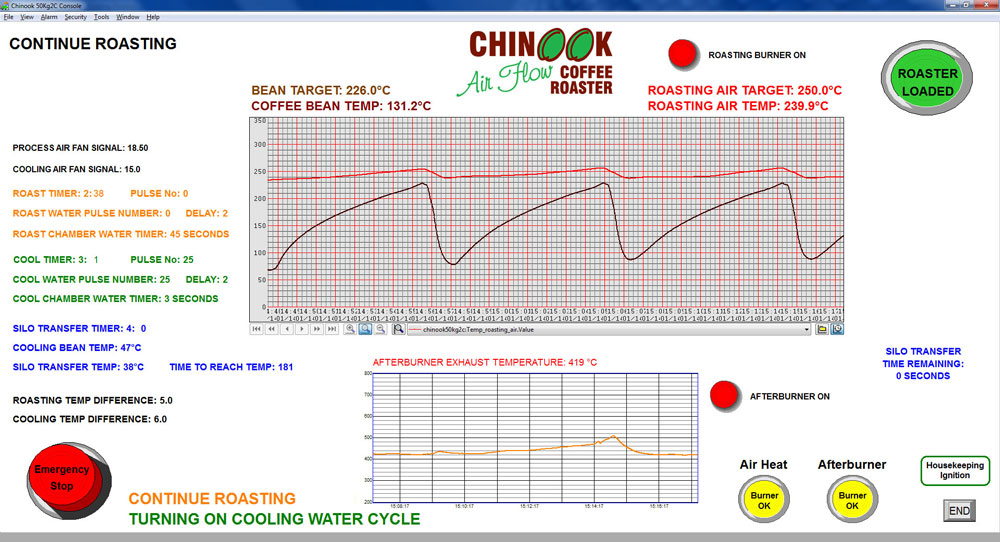

Air roasting using the industry standard Rotating Fluidized Bed

Simultaneous roasting and cooling

Pneumatic transport of roasted coffee to any one of 4 roasted coffee silos

Pneumatic transport of roasted coffee from any roasted coffee silo to automated packaging

Automated removal of stones & metal larger than 1mm Ø during transport

Electronic stone removal during vacuum transport.

Light illuminates roasting chamber, cyclonic real time chaff removal

Green coffee weighed then transported to the roaster

Heat exchanging afterburner

2.3 Metric Tonnes each of 4 different coffees

Roasted coffee silos – the last step before packaging

A single operator controlls all aspects of the roasting process

Easy to understand roasting controll console software