OCKHAM’S RAZOR dictates that It is pointless to do with more what can be accomplished with less

The problem (in this case, coffee roasting) should be no more complicated than required.

Conventional coffee roasters have evolved significantly over the last 100 years. Unfortunately, each improvement seems to result in greater complexity.

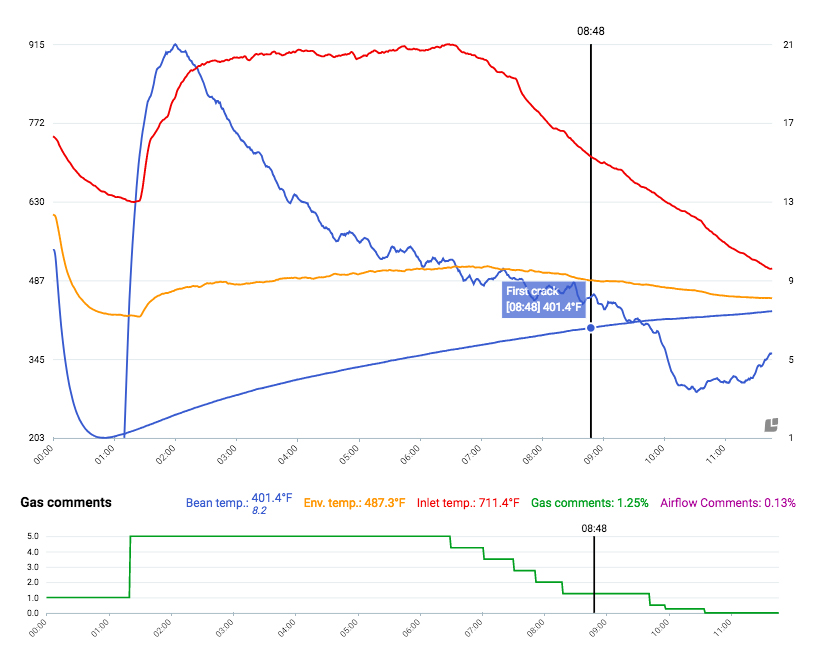

A typical roasting graph

Precision coffee roasting requires accurate real-time measurement:

- bean temperature while roasting

- temperature of the heating medium

Elegant Simplicity is a corollary to OCKHAM’S RAZOR

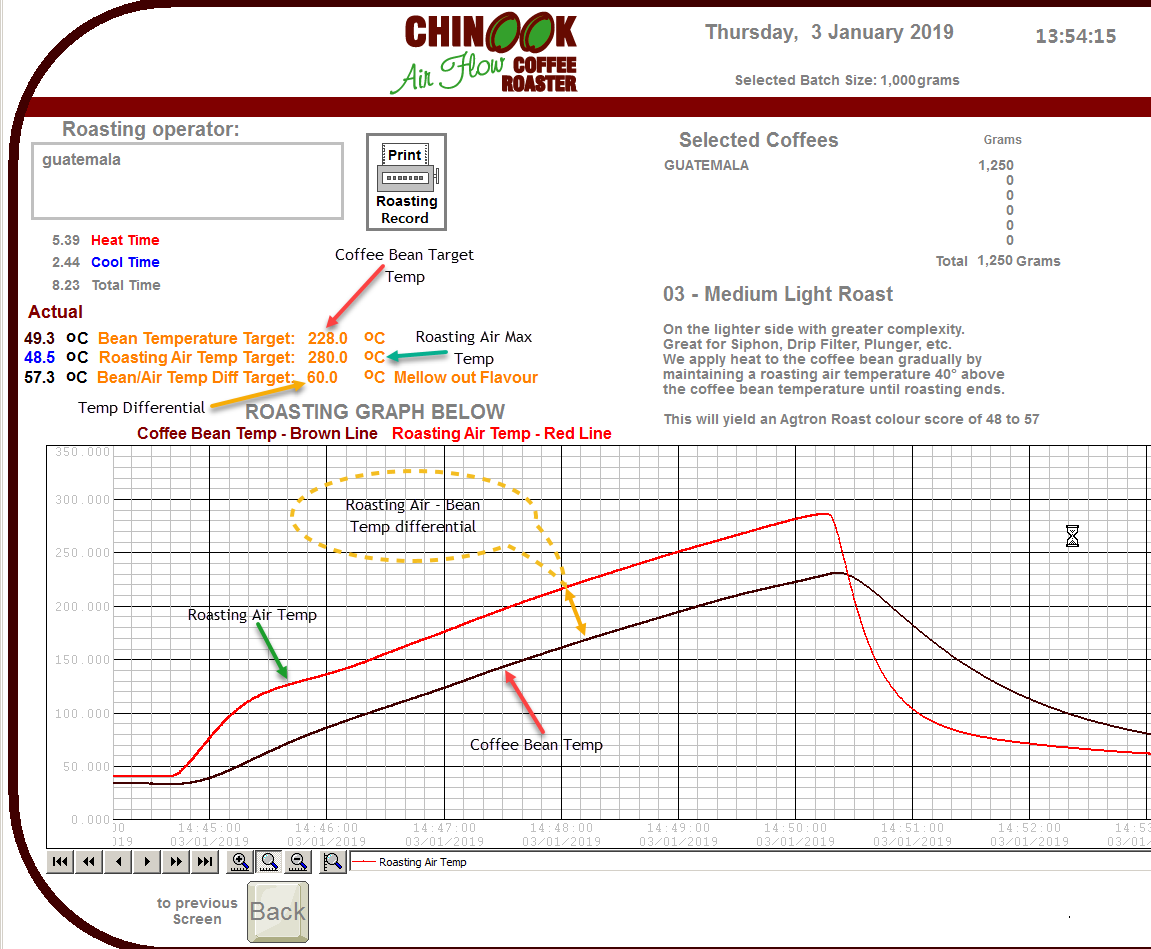

The design of Chinook coffee roasters is elegantly simple.

- The roasting coffee beans are suspended & mixed on a cushion of air.

- The heated fluidized air bed roasts all coffee beans evenly

- The roasting air and coffee bean temperature are monitored 10 X per second.

- The roasting air temperature is adjusted as required 10 X per second.

NOTE at right, the roasting air temp & coffee bean temp differential setting is 60 °C.

This causes the Chinook control system to apply heat that is 60 °C greater than the coffee bean temperature throughout the roasting process.

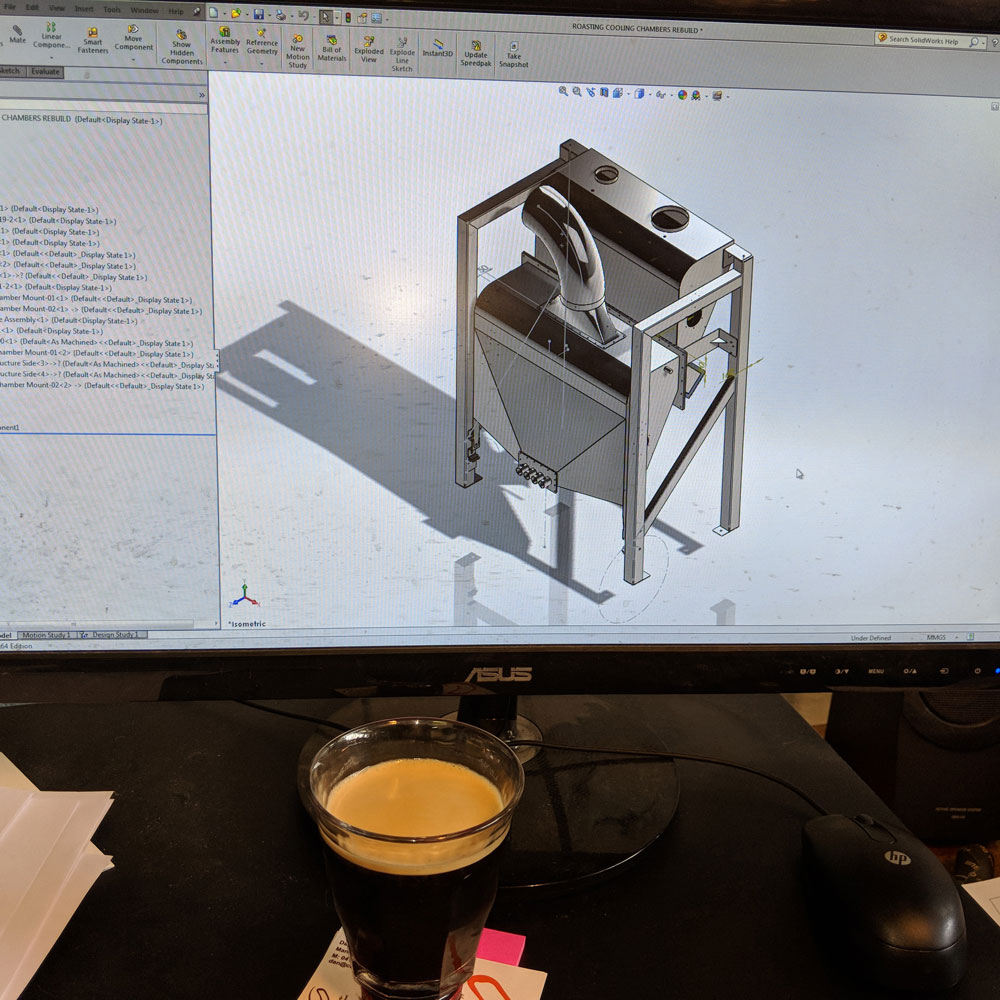

3 Dimensional modelling allows Chinook coffee roasters to be designed & behaviour tested prior to manufacturing

Using Flow Simulation we Simulate the airflow and heat transfer that are critical to the success of our Air Coffee Roasting designs.

All components in the roasting are checked for precision fit and hole alignment.

Every component that opens, shuts, rotates, slides, etc is exercised to assure interference-free operation.

Chinook coffee roaster – designed for accuracy & consistency

Avoid the time and expense of learning to operate complicated inefficient conventional roasting appliances.

Embrace the Chinook approach and become productive in hours.